A perfect product can only be produced from a perfect tooling.

SKY-WISE MOULD’s experienced and skilled tooling team is committed to building high-quality production toolings for clients from all over the world.

We understand that time to market is the essence of any project. Over the past years, our management team has spent highest attention to enhancing our efficiency and quality in order to complete projects in the quickest possible timeframe.

Tooling manufacture

Fast facts

Workforce: 60 employees,including 10 CAD/CAM Engineers, 4 Project Engineers;

Capability: 30-40 sets mold per month,maximum mold weight 20 tonnes;

Mold type: Large to precision molds,Multi-cavity molds, Hot runner molds,2-shot molds, Over molds, Insert molds,Unscrewing molds,Hydraulic Core molds,Prototype Molds .

Mold applys for: Auto parts, Electronics, Medical, Industrial,Household appliances etc.

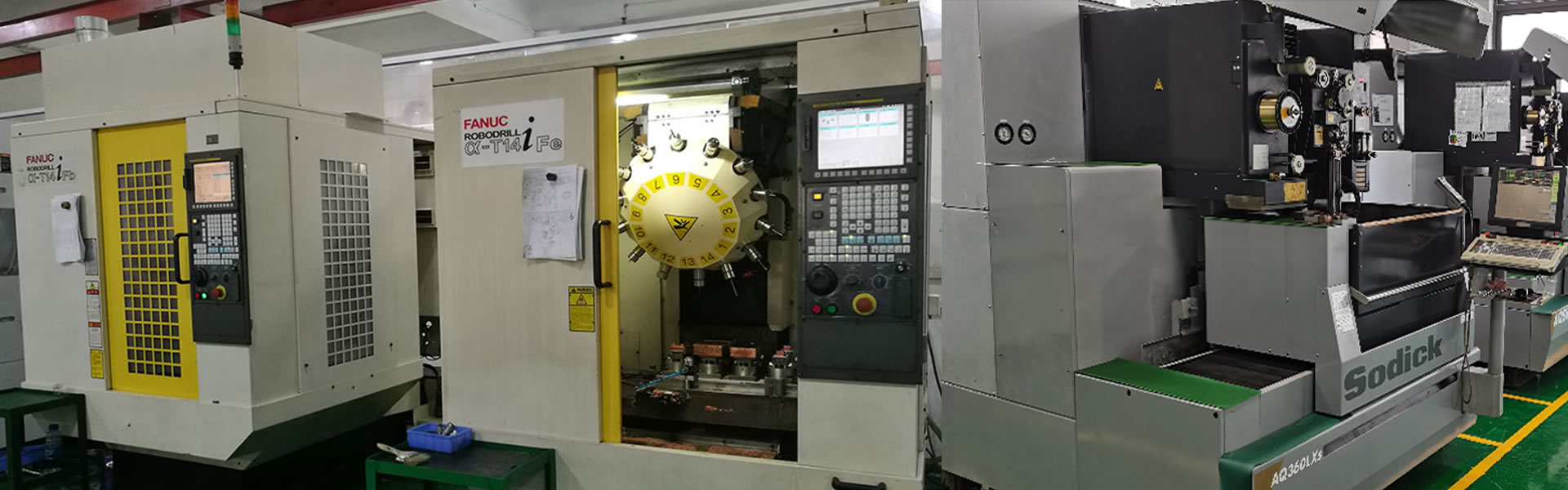

With well experienced engineering team, in-house trained tool makers and state-of-the-art machinery, SKY-WISE MOULD is capable of making molds with competitive price, efficient lead time and superior quality that you need.

| Equipment list 设备清单 | ||||||||

| No. 序号 |

Machine name 设备名称 |

Machine model 设备模型 |

Stroke (X*Y*Z) 行程 mm |

转数 RPM |

Accuracy 精密度 mm |

Origin 原产国 |

Qty 数量 |

Remark 备注 |

| 1 | High peed CNC | FANUC α-T14iFb | 500*400*330 | 24000 | 0.005 | Japan | 2 | |

| 2 | High peed CNC | JDLVM400T-A10S | 400*400*200 | 32000 | 0.002-0.005 | China | 2 | |

| 3 | CNC | YCM CV56A | 560*400*450 | 10000 | 0.01 | China Taiwang | 1 | |

| 4 | CNC | YCM MV106A | 1020*600*600 | 10000 | 0.01 | China Taiwang | 3 | |

| 5 | CNC | DAHLIH MCV-1200 | 1200*600*500 | 10000 | 0.01 | China Taiwang | 1 | |

| 6 | CNC | AWEA NVP-2012 | 2000*1200*760 | 10000 | 0.01 | China Taiwang | 1 | |

| Sub-Total | 10 | |||||||

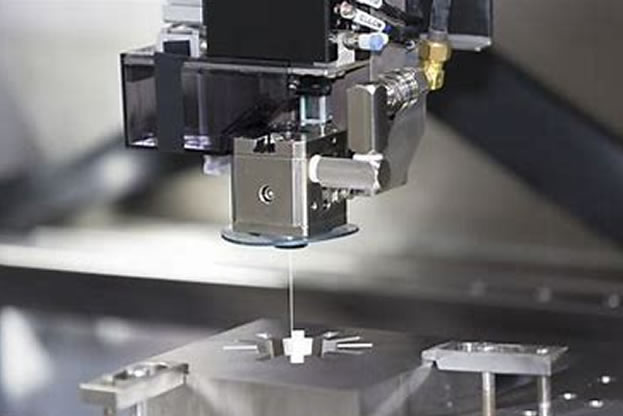

| 7 | Slow-feeding Wire-cut | SODICK AQ360LXS | 360*250*250 | / | 0.005 | Japan | 1 | |

| 8 | Slow-feeding Wire-cut | SODICK AQ560LXS | 560*350*300 | / | 0.005 | Japan | 1 | |

| 9 | Fast-feeding Wire-cut | DK7735 | 350*450*400 | / | 0.012-0.015 | China | 3 | |

| 10 | Fast-feeding Wire-cut | DK7745 | 450*550*400 | / | ≤0.02 | China | 1 | |

| Sub-Total | 6 | |||||||

| 11 | MIRROR EDM | DR1800HR | 1200*700*500 (Two-head) |

/ | ≤0.013 | China | 1 | |

| 12 | EDM | DM1470M CNC-EDM | 850*700*500 (Two-head) |

/ | ≤0.013 | China | 1 | |

| 13 | MIRROR EDM | DM40B | 400*500*320 | / | 0.01 | China | 3 | |

| 14 | MIRROR EDM | DM30B | 300*210*270 | / | 0.01 | China | 2 | |

| 15 | EDM | Topedm DF-545 | 500*400*220 | / | 0.01 | China Taiwang |

2 | |

| Sub-Total | 9 | |||||||

| 16 | Large grinder | KGS-306AH | 660*370*540 | 1450 | 0.003 | China Taiwang | 2 | |

| 17 | Grinder | KGS-618M | 475*185*370 | 2850 | 0.002 | China Taiwang | 7 | |

| Sub-Total | 9 | |||||||

| 18 | Miller | XK0816S | 220*160*220 | 1500 | 0.01 | China | 3 | |

| 19 | Miller | 220*160*220 | 1500 | 0.01 | China | 2 | ||

| Sub-Total | 5 | |||||||

| 20 | Radial drilling machine | ZQ3032X9 | 600*460*120 | China | 1 | |||

| 21 | Electric tapping | RC-16 | China | 1 | ||||

| 22 | Fitting machine | NC150-1511 | China | 1 | 150T | |||

| 23 | Laser marking | HD-TSGQW20 | China | 1 | ||||

| Sub-Total | 4 | |||||||

| 24 | CMM | Leader Miracle Nc685 | 600*800*500 | / | / | China | 1 | |

| 25 | Overhead projector | / | / | China | 1 | |||

| 26 | Height gauge | / | / | China | 1 | |||

| 27 | Rockwell hardometer | HR-150A | / | / | China | 2 | ||

| Sub-Total | 4 | |||||||

| 28 | Injection machine | HAITIAN MA5300II/4000 | / | / | / | China | 1 | 530T |

| 29 | Injection machine | HAITIAN MA3200/1700 | / | / | / | China | 1 | 320T |

| 30 | Injection machine | HAITIAN MA2000II/J1 | / | / | / | China | 1 | 200T |

| 31 | Injection machine | HAITIAN HTF160/J1 | / | / | / | China | 1 | 160T |

| 32 | Injection machine | HAITIAN MA120T | / | / | / | China | 1 | 120T |

| 33 | Injection machine | MA90T | China | 6 | 90T | |||

| Sub-Total | 11 | |||||||

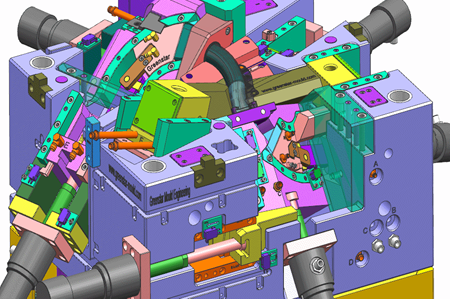

Mold designing

Our Mold design team’s capabilities are:

Perform DFM (Design for Manufacturability) analysis to ensure tooling and production friendly designs. After customer feedback on the DFM analysis reports, related modifications are made on the part design for clients' approvals prior to start of tool manufacturing.

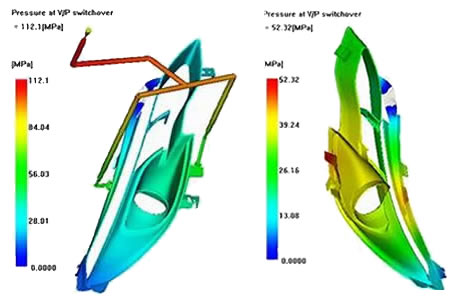

Perform Mold Flow analysis to gain insights into the Injection molding process (filling, cooling ,warping,and weld line and injection point) for achieving the most optimized mold design.

Our vast experience gives us the advantage for customized design to meet every client's specific needs. We are well-versed in using hot runner system and standard components from globally renowned brands like:

- Moldbase: Hasco/DME/Meusburger/Misumi etc.

- Hot runner: Yudo/Husky/INCOE/SYNVENTIVE etc.

- Oil cylinder: AHP MERKLE/HPS/Parker etc.

|

|

|

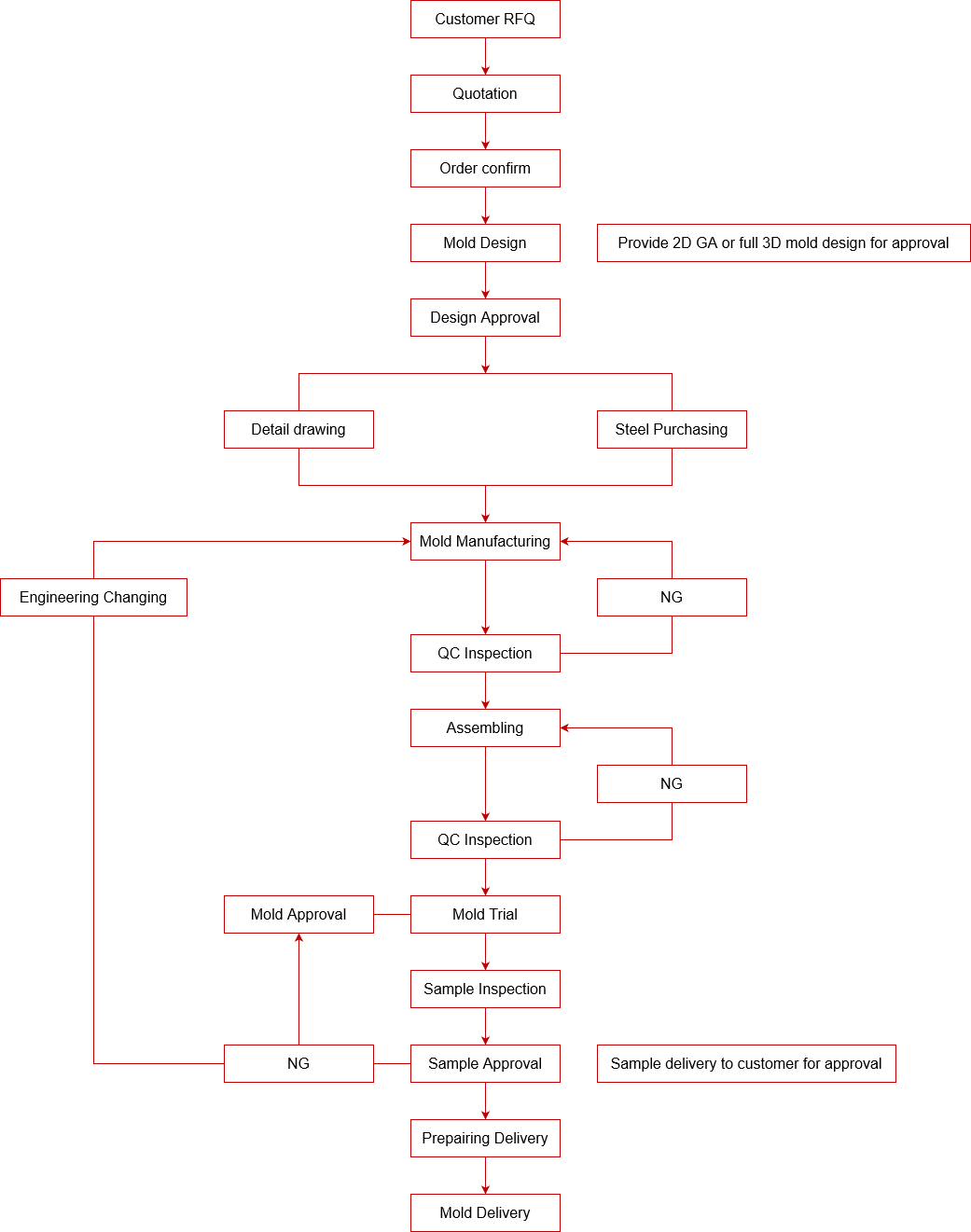

Project management

For each project, we will be very careful and arrange one project engineer to manage it from the very beginning design stage to mold and part final approval. We have a wonderful project management team, who owns strong engineering background and good English communication, this helps your project goes smoothly and well under control. Project manager always take care of every detail, and give you good suggestion to get better and easier tooling. Any problem happen, our professional project manager will stand by to solve the problem together with you, to find the best solution, that's very helpful.

Our company always do our best to control your project at every progress:

- Cost Control

- Design Control

- Engineering and Manufacturing Control

- Time Control

- Quality Control

Project flow chart:

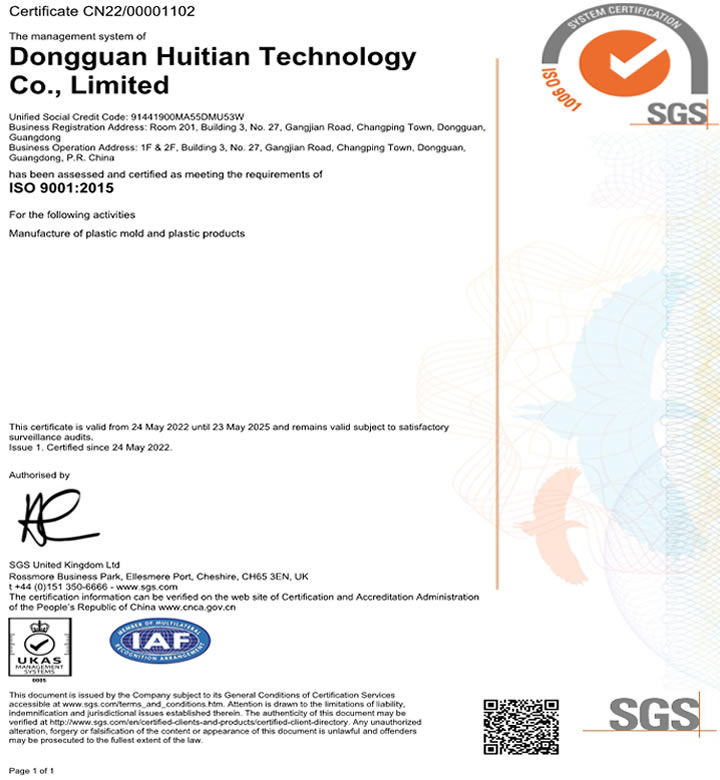

Quality assurance

All activities performed at SKY-WISE MOULD each division are folow to ISO9001:2015. SKY-WISE MOULD quality management system is designed to assure superior quality and service.

• Inspect all electrode dimension for every project

• Provide steel certification, and heat-treatment report.

• Calibrate our inspection machines every year

|

|

|